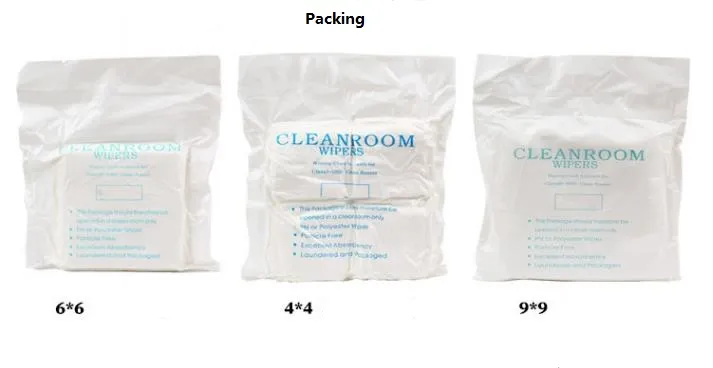

Cheap 1009 Clean-Room Wipes Polyester Lint-Free Wipers

Cleanroom wipe is widely used in the fields of optoelectronics, electronics, precision instrument manufacturing, semiconductor production lines, etc. Generally, there are three commonly used cutting methods for cleanroom wipe cutting technology,namely mechanical cutting, laser cutting and ultrasonic......

Send Inquiry

Product Description

Cleanroom wipe is widely used in the fields of optoelectronics, electronics, precision instrument manufacturing, semiconductor production lines, etc.

Generally, there are three commonly used cutting methods for cleanroom wipe cutting technology,namely mechanical cutting, laser cutting and ultrasonic cutting.

Cutting Methods

Cold cutting( Mechanical cutting): It is mainly cut directly by electric scissors. This cutting method is easy to produce dander, and it can't be cleaned. It will produce dander on the edge during wiping. It has low cleanliness. It is generally not recommended for high requirements.

Laser cutting: through the laser high-temperature melting, the edge sealing is better, no chipping phenomenon, and can be cleaned after the cutting, so that this method can meet the high cleanroom standard. The disadvantage is that because the edge is blown, it will be a bit harder, so if be careful in the process of wiping, there is usually no problem .

Ultrasonic cutting: The vibration generated by the ultrasonic vibration group (vibrator) (converts electrical energy into mechanical energy), passes the heat through the HORN (welding head), and then breaks the fabric through the cutter. It is the most perfect cutting methods, and the edge sealing effect is good and the edges are not hard, but this method is relatively costly.

Classification

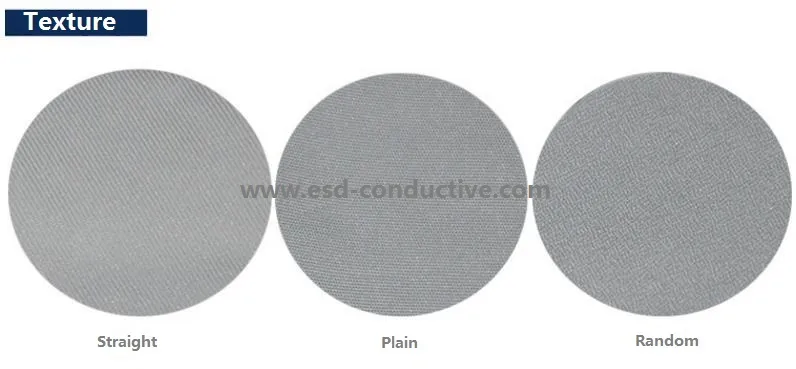

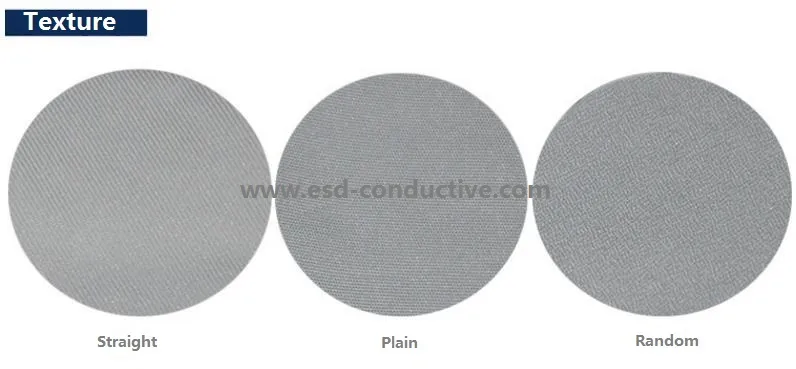

By the differences of the texture,cleanroom wipes could be classified as Straight,plain/girds, random wipes.

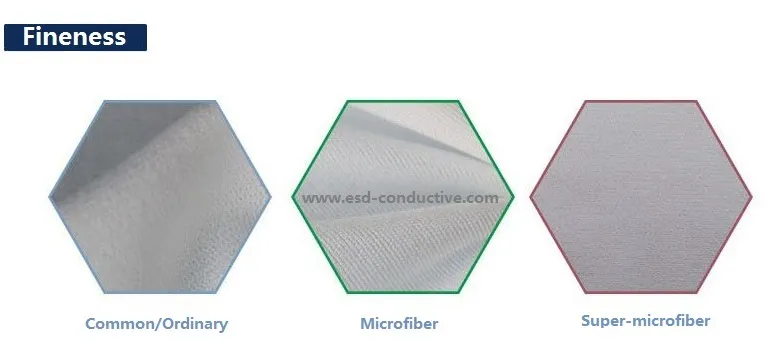

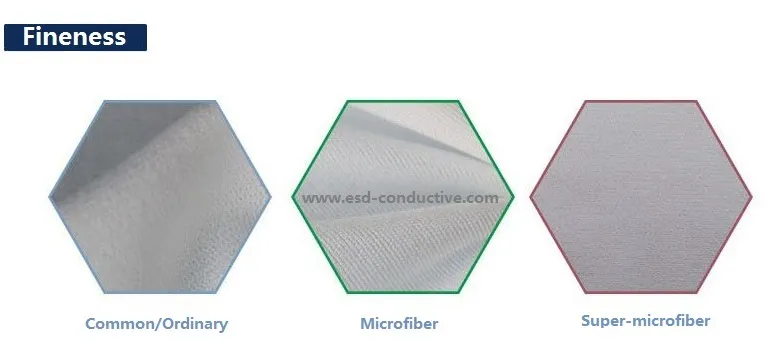

By the fineness, it could be classified as common/ordinary,microfiber,super-microfiber wipes

Generally, there are three commonly used cutting methods for cleanroom wipe cutting technology,namely mechanical cutting, laser cutting and ultrasonic cutting.

Cutting Methods

Cold cutting( Mechanical cutting): It is mainly cut directly by electric scissors. This cutting method is easy to produce dander, and it can't be cleaned. It will produce dander on the edge during wiping. It has low cleanliness. It is generally not recommended for high requirements.

Laser cutting: through the laser high-temperature melting, the edge sealing is better, no chipping phenomenon, and can be cleaned after the cutting, so that this method can meet the high cleanroom standard. The disadvantage is that because the edge is blown, it will be a bit harder, so if be careful in the process of wiping, there is usually no problem .

Ultrasonic cutting: The vibration generated by the ultrasonic vibration group (vibrator) (converts electrical energy into mechanical energy), passes the heat through the HORN (welding head), and then breaks the fabric through the cutter. It is the most perfect cutting methods, and the edge sealing effect is good and the edges are not hard, but this method is relatively costly.

Classification

By the differences of the texture,cleanroom wipes could be classified as Straight,plain/girds, random wipes.

By the fineness, it could be classified as common/ordinary,microfiber,super-microfiber wipes

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.